Description

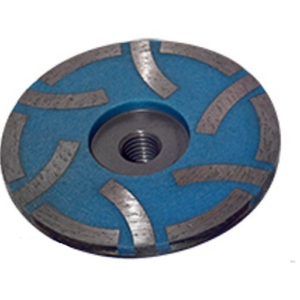

Alternating Segs Provide PCD Protection & Stable Balance for Improved Finish!

Professional Quality, Quarter-Round, PCD Diamond Cup Wheels, with Protective, Under-Seg®, aggressively grinds concrete and removes epoxy, urethane, mastic and concrete coatings at the fastest removal rates.

Alternating, Under-Seg ® design, provides more stable grinding and protective functionality to prevent PCD diamonds from getting jarred and coming apart from steel base.

The combined PCDs and alternating diamond protective segments, improve the overall cosmetic finish to the concrete surface and provides improved performance and longevity.

Quarter-Round, PCD Diamond Cup Wheels, feature special cooling holes to reduce heat during dry grinding for improved efficiency and optimum performance. Computer balanced for smooth, vibration free operation.

- Size: 4″, 4.5″, 5″, 7″

- Arbor: 5/8″-7/8″ Arbor | 5/8″-11 Thread

- Design: Large Quarter-Round PCD + Protective Seg

- Wet & Dry

- Item#: CUP PCD-U

What are PCD Diamonds?

Diamond Tec USA, Polycrystalline Diamond (PCD) Cup Wheel, are made with micron-sized synthetic diamond powders bonded together by sintering at high pressures and temperatures.

Polycrystalline Diamond (PCD), are produced on a cemented carbide substrate utilizing our propitiatory cobalt sintering process. The cobalt from the cemented carbide substrate infiltrates through layers of micron synthetic diamond powder, causing grains to grow and bond together.

As a result, the cobalt is significantly condensed, delivering the critical material for the hardest produced diamond material.

The integrally bonded carbide substrate allows for the brazing of the PCD material for a stronger and overall harder bonded diamond tool.

Reviews

There are no reviews yet.